Electric Hammer Drill 28mm Zh2-28

Parameter

Input power:

Maximum drilling diameter (steel):

Maximum drilling diameter(wood):

Maximum drilling diameter (concrete):

Maximum drilling diameter brick (with hollow bit):

Rated speed:

Hammering rate:

Maximum single blow force:

Weight:

Machine size:

Clamping system:

820W

13 mm

30mm

28 mm

68mm

0-1300 rpm

0-5100 times/min

3.2 joules (based on EPTA standard)

2.8kg

350x88x210mm

SDS plus

Advantages

The pre-operation inspection should meet the following requirements:

1. No cracks or damage on the shell and handle;

2. The cable cord and plug are intact, the switch operates normally, and the protection zero connection is correct, firm and reliable;

3. The protective cover of each part is complete and firm, and the electrical protection device is reliable.

Second, after the machine tool is started, it should be run without load, and the machine tool linkage should be checked and confirmed to be flexible and unimpeded. During operation, the afterburner should be stable, and no excessive force should be applied.

3. The electric drill or hammer handle should be mastered during the operation, and the drill bit should be pressed against the work surface of the special-shaped rivet before drilling, and then it should be driven with moderate force to avoid shaking; if the speed drops sharply, the force should be reduced to prevent the motor from being overloaded. Carry pressure.

Fourth, when drilling, you should pay attention to avoid the reinforcement in the concrete.

Fifth, the electric drill and the electric hammer are 40% intermittent working system, and may not be used continuously for a long time.

Sixth, when the operating aperture is more than 25mm, there should be a stable operating platform, and guardrails should be set around.

Seven, overloading is strictly prohibited. Attention should be paid to the sound and temperature rise during the operation. If any abnormality is found, the machine should be shut down and checked immediately. When the operation time is too long, and the temperature rise of the machine exceeds 60°C, the machine should be stopped, and the operation should be carried out after natural cooling.

8. When the machine rotates, don't let go.

9. During operation, do not touch the electric saw blade, die and grinding wheel with your hands. If it is found to be blunt or damaged, you should immediately stop the machine for repair or replacement, and then continue the operation.

Application scenarios of electric hammer

Widely used in construction, decoration and other industries, suitable for concrete,Brick wall, stone, etc

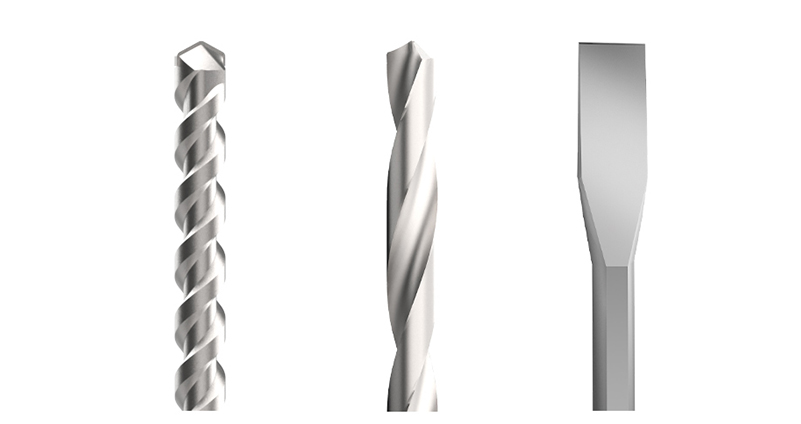

Electric drill function--With impact (mechanical CAM principle)

Suitable for concrete, brick wall, stone impact drilling and wood, metal,Ceramic tile drilling operation

Gravel broken wall

chisel groove slot

Piercing punch

Crushed stone chisel wall

Crushed stone chisel ground

Board perforated

Electric hammer comparison:

500W input powerful

Dont let bad product drag

wall in weak Motor not durable The oil is easy to leak .

Our products will solve this all problems

Plastic Blowing Box

Company Profile